Casting

Jaypee Hitech Casting Centre (JHCC),a world class Steel Castings Shop, adjacent to and synergizing with Heavy Engineering Workshop (HEW), is operating under same management.

This state-of-art steel casting facility incorporating automatic & semi-automatic steel casting lines built in collaboration with world class OEMs e.g. DISA of Denmark for Green Sand type and IMF of Italy for No-bake type products, had been commissioned in October’11. Its capacity for casting all types of products, including Hi-chrome, HRCS, other Alloy Steel and Manganese Steel types works out to be about 1500 tonnes per month (or 18000 tonnes per year). This futuristic plant mainly caters for following industries in this country:

“Cement Plants, Steel Plants, Power Plants, Material Handling Equipment, Sugar Industry and other engineering industries”

Salient Features:

JAL has put up a state-of-the-art Alloy Steel Foundry to cope up with the requirement of Wear Resistant Castings for various industrial applications, such as Grinding Media for Ball Mills, Liners for Ball Mills for Limestone & Coal, Liners for Vertical Mills for Limestone, Coal, and Clinker Grinding, HRCS Castings for Kiln & Cooler applications in Cement Plants and in general Wear Resistant Liners for all industrial applications. We specialize in such wear resistant castings and sophisticated Alloy Steel Castings both for conventional ball mills and the newer trend for high-productivity and higher power-efficiency Vertical Mills of Cement Plants and Power Plants. Our range of manufacture includes Hi-Chrome Steel, Manganese Steel, HRCS and any other Alloy Steel to customer requirements.

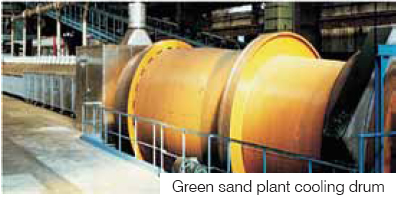

Green Sand Line

For Grinding Media a completely automated Green Sand Plant is supplied by M/s DISA, Denmark who are world leaders in Green Sand Automated Line. It gives us a triple advantage of higher quality, higher productivity and equally important minimized environment impact. A very special feature of this line is that we have provided for fettling of the Balls also in a mechanized way which is completely a new feature even with an automated line.

For Grinding Media a completely automated Green Sand Plant is supplied by M/s DISA, Denmark who are world leaders in Green Sand Automated Line. It gives us a triple advantage of higher quality, higher productivity and equally important minimized environment impact. A very special feature of this line is that we have provided for fettling of the Balls also in a mechanized way which is completely a new feature even with an automated line.

No Bake Line

For other components No Bake Plant is supplied by M/s IMF, Italy – world leader for supply of No Bake Plants. We are equipped to make castings up to 12 tonnes weight. For fettling of such castings we have completed automated grinding stations with heavy duty 3 Axis Manipulator supplied by M/s Clansman of Scotland. This line will cope up with production of larger castings for cement plants and power plants etc. Care has been taken to include adequate plant for treatment of used sand so that the new sand usage will be less than 10% of total sand used.

Manufacturing Facilities Major Equipment Suppliers Hi-tech Casting Installed capacity of each plant viz. Green Sand Plant and No Bake Plant is 9000 TPA giving a total installed capacity of 18000 TPA. We expect to use 50% of our capacity for our captive requirements in our cement plants and power plants and balance is available to meet demand for such high grade Alloy Steel Castings in the market.